Overview | Equipment | Sectors | Other Services | Contact

Specialists in the precision machining of prototype and production castings

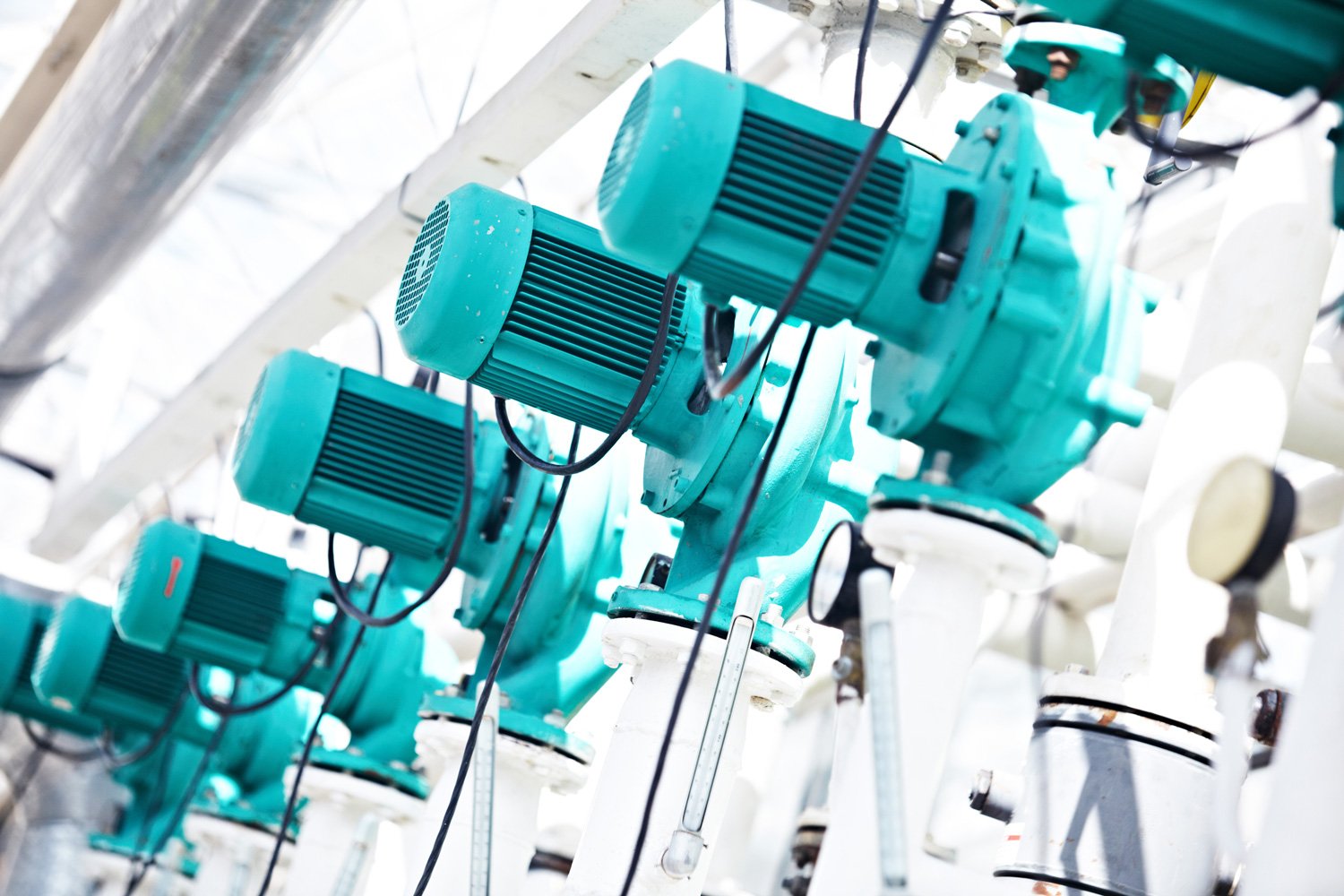

Our rapidly expanding precision machining facility provides a range of equipment to offer customers a variety of engineering solutions for prototype and productions castings sourced from within the Newby Foundries Group.

700m² Facility

6 Vertical CNC Machining Centres

3 CNC Lathes

1 CNC CMM

Would you like to discuss a project?

Telephone: +44 (0) 121 556 4451

Email: sales@newbyfoundries.co.uk

Quality Management System

Full time on-site Quality Manager

Complex Compound Machining

Continuous 5 axis CNC machining centre

Dedicated Assembly Area

Machined parts can be supplied fully assembled

Equipment

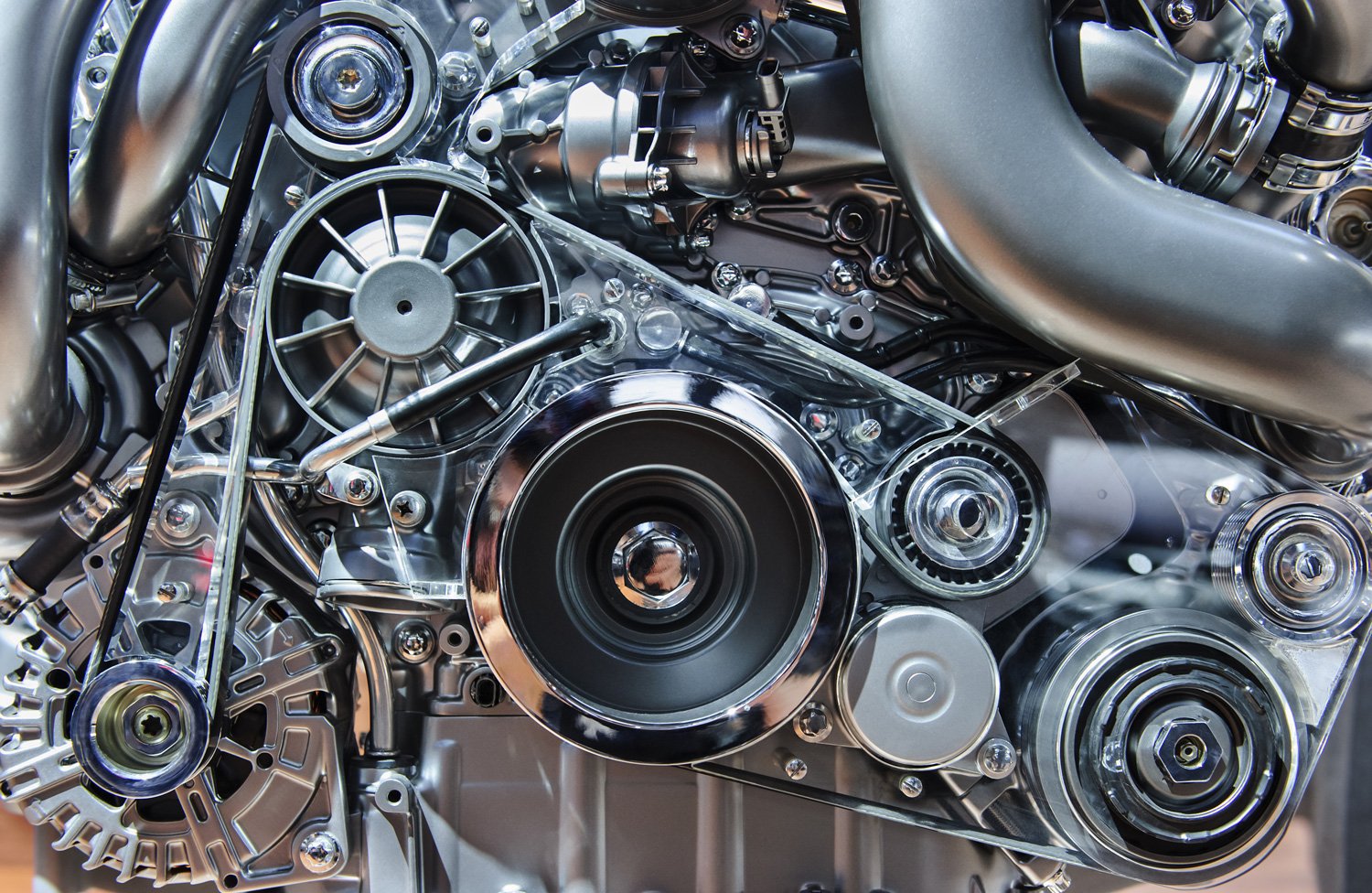

Available equipment includes a 5 axis CNC machining centre, 6 vertical CNC machining centres including one with twin pallets, and 3 CNC lathes. This means we have the capabilities and capacity to complete many complex milling and turning operations. We also have air decay pressure testing, ultrasonic wash facilities and a CMM with measure to CAD to ensure a high quality is maintained. Machined castings can also be supplied fully assembled in our dedicated cell. Where necessary, to support our in-house machining facility, we sub-contract work to suppliers to increase capacity and add available processes.

5 Axis CNC Machining Centre

1 x Hurco MX60 SRTi

Vertical CNC Machining Centres

2 x Hurco VM1

1 x Leadwell MV40i

1 x Hurco VM20i

1 x Doosan 6700

1 x Doosan VC 510

Twin Pallet

CNC Lathes

1 x Puma GT2600M

1 x Lynx 2100LM

1 x Lynx 220LM

Other Equipment

Aberlink Zenith 3 CNC CMM

1500 x 1000mm

Measure to CAD

Air decay pressure test facilities

Ultrasonic wash facilities

Assembly

Sectors

Newby foundries precision machining operate in the following industries:

Our broad customer base spans many sectors and industries including automotive, rail, construction and general engineering OEMs. Examples of castings we produce include rocker covers, turbo components, manifolds and valves.

Other Services

Discover the services Newby Foundries Precision Machining can also assist with:

QUALITY

Dimensional analysis reports

Pressure test reports

Cleanliness testing

PPAP & FMEA

FINISHING

Grinding

Heat treatment

Balancing

Painting

Deburring

Etching

Visual inspection

managed supply

Increased capacity

Additional processes available

Expert oversight

Tier one management

Divisions

EXPLORE THE NEWBY FOUNDRIES GROUP

The Newby Foundries Group produce high quality castings in a variety of materials, sizes & finishes across our 4 sites. Our range of casting processes, combined with our ability to develop castings from prototype through to production means we can provide customers with an optimal casting solution for many applications.

We are continually investing in new technologies and expanding our facilities to deliver a full range of cutting edge solutions

Would you like to discuss a project?