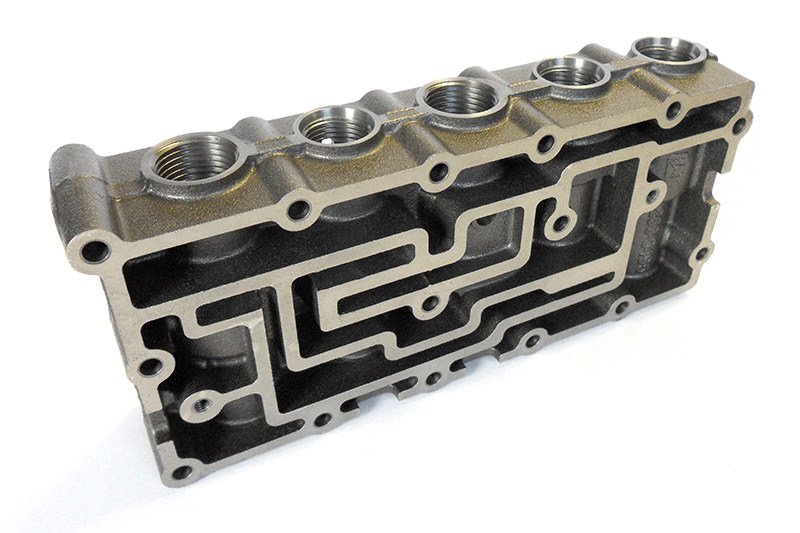

Specialists in the production of high quality shell & airset castings in various grades of iron

Our large purpose-built facility in the West Midlands primarily produces complex, high tolerance shell and airset castings for a variety of industries in various grades of iron.

16,000m² Facility

10,000kg of Iron Cast Daily (Single Shift)

5 Induction Furnaces

4 Two Station Shell Moulding Machines

Would you like to discuss a project?

Telephone: +44 (0) 121 556 4451

Email: sales@newbyfoundries.co.uk

100kg High Tolerance Castings

Facilitated by our unique vacuum backed shell moulding process to CT9 tolerance.

High or Low Volume Runs

From tens to tens of thousands, we have the flexibility to cater for both.

IATF & ISO Quality Management

Accredited to both IATF 16949 & ISO 9001 for the shell & airset processes.

Processes

Primarily our iron foundry produces castings using the airset, shell moulding and unique vacuum-backed shell moulding processes but we also have greensand capabilities and an in-house 3D sand printer. Therefore, we can provide customers with the most suitable casting solution for many applications. Our range of processes also enables us to produce cost-effective casting iron in various quantities from tens to tens of thousands.

Find out more about the processes we offer below.

Shell & vacuum backed shell moulding

Medium to high volume

Plate size 600x400mm

Up to 100kg

CT9 tolerance

IATF 16949

Fine surface finish

High strength cores

Airset moulding

Low to medium volume

Up to 250kg

CT10 tolerance

Cold box core blowing

Low to high volume

CT9 tolerance

Low cost tooling

Greensand moulding

Low or batch volume

Up to 20kg

CT12 tolerance

3D Sand Printing

Furan system

1,800 x 1,000 x 700mm bed size

Layer thickness: 280 - 500μm

No tooling required

Undercuts possible

CT10 tolerance

Materials

We manufacture iron castings in a range of grades including grey, ductile, and vermicular irons, and alloy irons such as NiResist and SiMo. Customer specific grades are also available on request. Our 5 induction furnaces allow us to change grades within minutes and cast parts weighing from as little as 200g up to 250kg.

We can produce all grades of the following materials. Non-standard and customer specific grades are available on request.

Grey irons

High compression strength & dampening qualities.

Ductile irons

(spheroidal graphite, SG, or nodular) Ductile with a high tensile strength.

Vermicular graphite irons

Characteristics in-between grey and ductile irons.

Austempered ductile irons (ADI)

Heat treated for increased strength & wear resistance.

SiMo (Silicon Molybdenum) irons

Resists oxidisation at high temperatures.

NiResist irons

Resistant to corrosion at high temperature.

Newby Foundries are committed to sourcing materials from companies that share our values in relation to human rights, ethics and environmental responsibility. We demand our suppliers comply with our code of conduct, and meet our sustainability expectations, including conflict free sourcing of materials. To ensure this commitment is fulfilled Newby Foundries ensures that its products are produced using only materials which can be proven to have originated from non conflict sources.

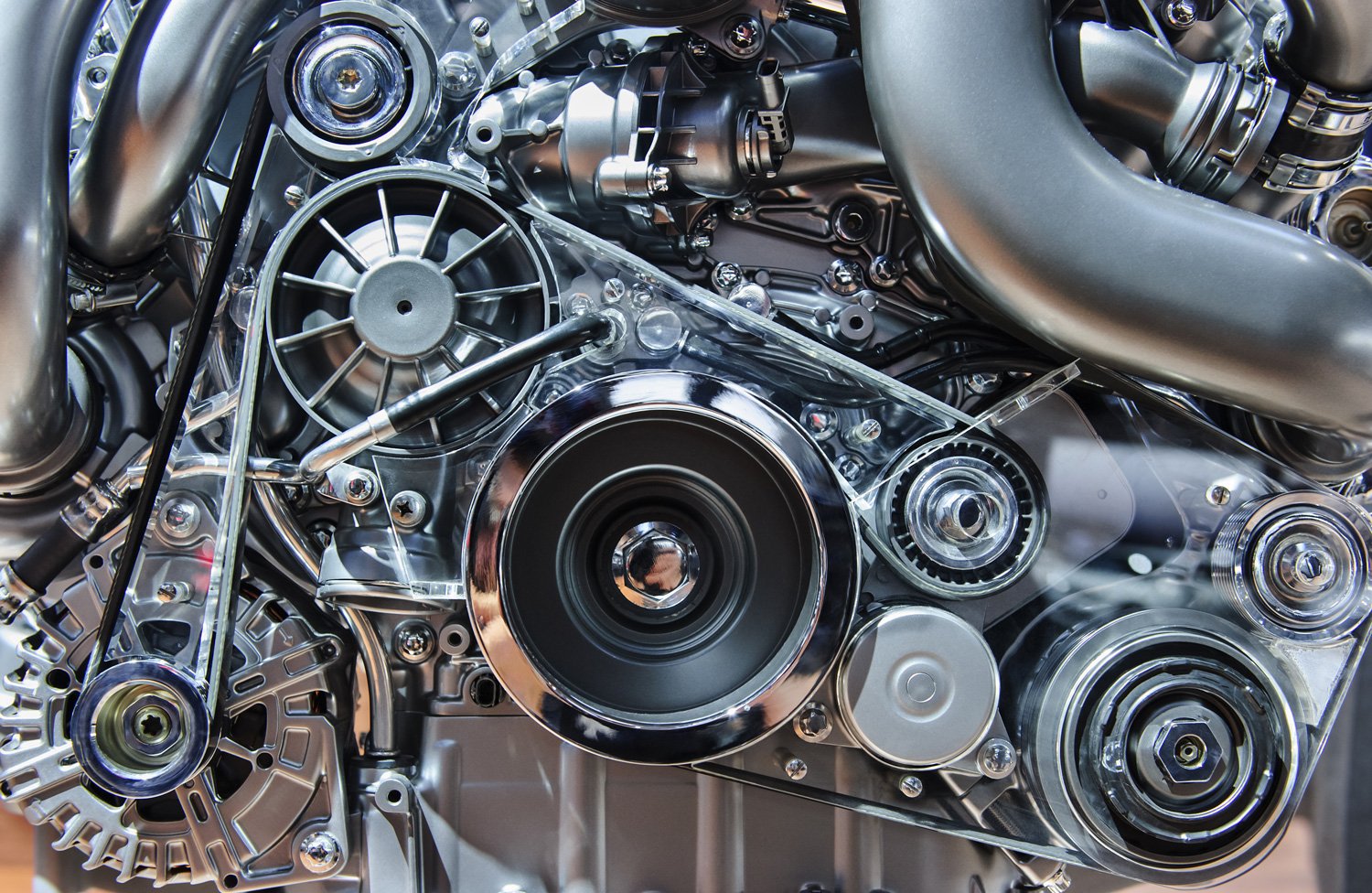

Sectors

Newby Casting iron foundries operate in the following industries:

We produce castings iron for a wide variety of OEMs in sectors such as automotive, hydraulic and pump components such as turbine housings, bearing housings, compressor covers, valve spools and pump bodies construction, pumps and hydraulics. We also make various general engineering castings.

Equipment

Design

5x SolidWorks CAD software licences

MagmaSoft casting simulation software

Core making

9x shell core blowing machines

Cold box core blowing machine

CNC core drilling robot

Melting

4x 550kg induction furnaces

1x 350kg induction furnace

16 element spectrograph

Moulding

1,800 x 1,000 x 700mm furan 3D sand printer

4 x 2 station polygram shell moulding machines

10 ton per hour airset mixer

Sand reclamation

Thermal sand reclamation plant

£1.2m investment in 2012

Self sufficient for coated shell sand

Sand laboratory facilities

Blasting

3x tumble blast machines

Table blast machine

Nozzle blast machine

Fettling

4x CNC fettling robot

Large CNC fettling robot

Measuring

3 axis coordinate measurement machine

7 laser 3D scanner

Other Services

Discover the services Newby Foundries Iron can also assist with:

Quality

Material testing laboratory

Dimensional analysis reports

PPAP & APQP

MPI, DPI & X-ray

Pressure testing

Ultrasonic testing

Finishing

Heat treatment

Pickling & passivating

Plating

Painting

Galvanising

Divisions

Explore the Newby Foundries Group

The Newby Foundries Group produce high quality castings in a variety of materials, sizes & finishes across our 4 sites. Our range of casting processes, combined with our ability to develop castings from prototype through to production means we can provide customers with an optimal casting solution for many applications.

Our market leading iron foundry produces quality castings with low lead times at competitive prices

Would you like to discuss a project?